-

Koszyk jest pusty!

MENU

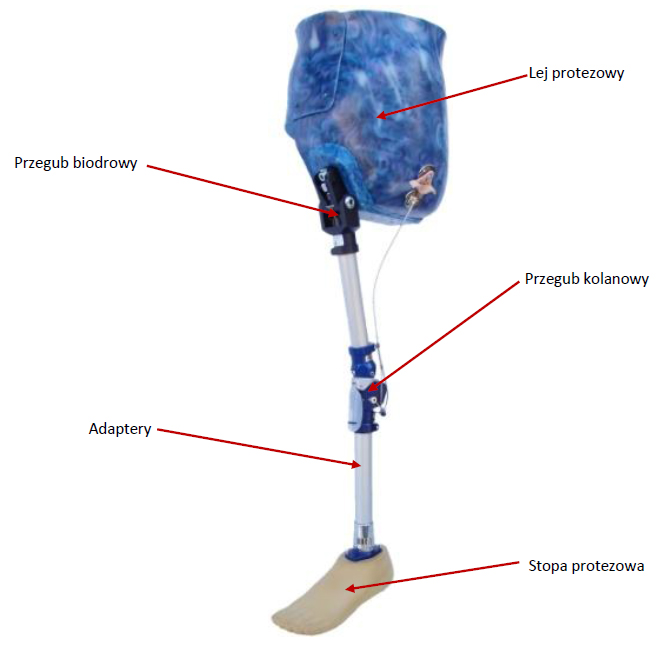

Modularne protezy kończyny dolnej należą do najczęściej użytkowanego zaopatrzenia ortopedycznego na świecie. Są to protezy stosowane w przypadkach Pacjentów po amputacjach w obrębie kończyny dolnej.

Lej protezowy – element ten jest wykonywany indywidualnie dla każdego Pacjenta w zakładzie ortopedycznym. Odwzorowuje on dokładnie kształt kikuta. Jest jednym z najważniejszych elementów protezy, ponieważ stanowi połączenie pomiędzy protezą, a ciałem amputanta i stanowi o komforcie używanej protezy. Wyróżniamy różne typy lejów ze względu na rodzaj amputacji, materiał leja oraz sposób jego przylegania do kikuta. Tendencja kikuta do zmiany swojej objętości stanowi jeden z największych problemów w protezowaniu.

Przegub biodrowy - Mechanizmy stawu biodrowego są istotnym aczkolwiek z reguły mało funkcjonalnym elementem protez z koszem biodrowym. Ze względu na bardzo małe zapotrzebowanie na tego typu konstrukcje powstało niewiele rozwiązań w tym zakresie. Wszystkie z obecnie znajdujących się na rynku przegubów biodrowych realizują swoją funkcję za pomocą sprężyn, bądź innych zderzaków z materiałów sprężystych. Brak jest rozwiązań z kontrolą pneumatyczną, hydrauliczną, bądź elektroniczną. Większość z tych mechanizmów to mechanizmy jednoosiowe. Ważnym elementem każdego przegubu biodrowego jest też element przytwierdzający protezę do kosza biodrowego. Najczęściej wykorzystywane protetyczne stawy biodrowe skupiają się w dużej mierze na stabilnej pozycji kończyny w czasie postoju oraz aktywnym wyrzucie protezy podczas fazy przenoszenia. Są to z reguły bardzo proste, mało awaryjne, niewielkie i lekkie konstrukcje. Wadami tych konstrukcji jest niska kosmetyka chodu oraz mała ilość rozwiązań w tym zakresie.

Przegub kolanowy- Przeguby kolanowe w protezach modularnych są bardzo istotnym elementem. Przegub kolanowy powinien zagwarantować pacjentowi stabilność protezy zarówno podczas stania jak i fazy podporu w trakcie chodzenia. W głównej mierze odpowiada on za bezpieczeństwo pacjenta. Steruje on także ruchem podudzia podczas fazy przenoszenia oraz powrotu do pozycji wyjściowej. W dużym stopniu od rodzaju stawu kolanowego zależy dynamika chodu pacjenta. Różnorodność przegubów jest bardzo duża, dlatego najważniejsza sprawą jest dobór odpowiedniego przegubu kolanowego do aktywności pacjenta, jego oczekiwań oraz potrzeb. Kolano protezowe powinno uwzględniać kilka podstawowych aspektów, a zagwarantowanie psychicznej pewności oraz odpowiedniej dynamiki pracy przegubu skutkuję chodem zbliżonym do naturalnego. Kolana protezowe możemy podzielić ze względu na ilość osi (jedno bądź wieloosiowe) oraz na mechanizm jaki wykorzystują. Wyróżniamy mechanizmy: policentryczne, pneumatyczne, hydrauliczne oraz sterowane elektronicznie.

Adaptery – Są to elementy łączące ze sobą poszczególne moduły konstrukcji. Mogą być wykonane z różnego rodzaju materiałów. Możemy je podzielić ze względu na to czy są bierne czy też funkcjonalne. Elementy bierne to na przykład adaptery rurowe, łączące, adaptery do laminacji – łączą one tylko poszczególne moduły protezy, nie spełniają żadnej funkcji. Natomiast adaptery funkcjonalne stwarzają protezie nowe możliwości, są to adaptery obrotowe, przesuwne, amortyzatory.

Stopa protezowa - Bardzo ważnym elementem protezy modularnej jest stopa protezowa. To, w jaki sposób zachowa się podczas kontaktu z podłożem będzie miało wpływ na zachowanie całej protezy. Z mechanicznego punktu widzenia stopy możemy podzielić na dwie proste kategorie. Są to stopy z ruchomym stawem skokowym oraz sztywne stopy pozbawione przegubu. Możemy także dokonać podziału ze względu na tworzywo z którego zostały wykonane. Istnieje bardzo dużo takich rozwiązań, co jest ogromną zaletą systemu protez modularnych w których dzięki temu można dopasować każdy mechanizm indywidualnie do zapotrzebowania użytkownika. Ze względu na rodzaj tworzywa, z którego zostały wykonane możemy wyróżnić stopy ze stawem mechanicznym, pneumatycznym, hydraulicznym, pneumatyczno hydraulicznym, oraz najbardziej popularne stopy z włókna węglowego. Najnowsze osiągnięcia to stopy elektroniczne z wbudowanym mikroprocesorem.

Sztandarowymi wyrobami firmy są przeguby protetyczne. Proponujemy przeguby biodrowe oraz kolanowe, dla różnych kategorii aktywności oraz ciężaru ciała. Dzięki wieloletniemu doświadczeniu firmy dostępne są przeguby kolanowe monocentryczne jak i policentryczne, z zamkiem oraz bezpieczne, regulowane jak i dostosowane do nietypowych warunków po amputacji. Natomiast nasze przeguby biodrowe posiadają możliwość regulacji aż w trzech płaszczyznach.

W ofercie naszej firmy znajduje się również wiele adapterów protezowych o różnym przeznaczeniu. Są to adaptery stopy protezowej, adaptery do laminacji leja protezowego, adaptery obrotowe, przesuwne śrubowe, tulejowe, zaciskowe, przedłużające, podwójne, rurowe oraz adaptery z pochyleniem skośnym.

Proponujemy także szereg zestawów ze starannie dobranymi elementami zdającymi egzamin przy Pacjentach o danej aktywności, ciężarze ciała oraz poziomie amputacji.

System modularny pozwala na łączenie, rozłączanie, zamienianie ze sobą poszczególnych elementów w dowolnej chwili. Dzięki zastosowaniu systemu modularnego większość elementów jest kompatybilna z wyrobami innych producentów.

Wszystkie elementy protez zostały wykonane z materiałów lekkich i wytrzymałych o najlepszej jakości. Szeroka gama produktów pozwala na dobranie oraz dopasowanie produktu do każdego człowieka – jego stopnia aktywności oraz ciężaru ciała , jak i indywidualnych wymagań co do funkcjonalności protezy.

Produkty Naszej firmy są systematycznie uzupełniane o najnowsze trendy na rynku, dlatego też w katalogu można znaleźć elementy konstrukcji protezy dla każdego potencjalnego użytkownika.

Należy jednak pamiętać, że ustawienie protezy jest jednym z ważniejszych elementów protezy. Możemy dysponować najlepszym przegubem kolanowym i stopą, ale ważny jest sposób ich zmontowania.