-

Koszyk jest pusty!

MENU

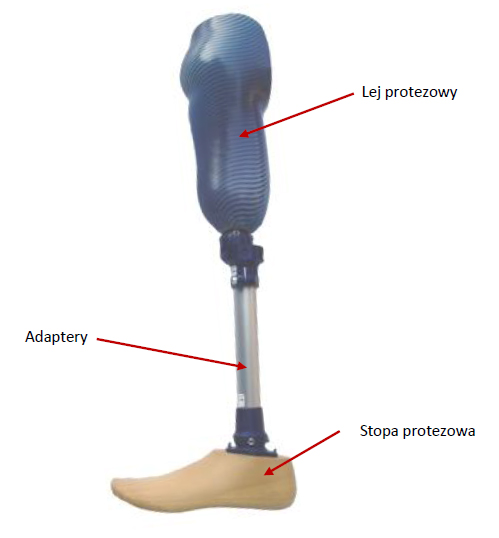

Modularne protezy podudzia są jedynymi z najczęściej użytkowanego zaopatrzenia ortopedycznego na świecie. Są to protezy stosowane w przypadkach Pacjentów po amputacjach poniżej kolana.

Lej protezowy – element ten jest wykonywany indywidualnie dla każdego Pacjenta w zakładzie ortopedycznym. Odwzorowuje on dokładnie kształt kikuta. Jest jednym z najważniejszych elementów protezy, ponieważ stanowi połączenie pomiędzy protezą, a ciałem amputanta i stanowi o komforcie używanej protezy. Wyróżniamy różne typy lejów ze względu na rodzaj amputacji, materiał leja oraz sposób jego przylegania do kikuta. Tendencja kikuta do zmiany swojej objętości stanowi jeden z największych problemów w protezowaniu.

Adaptery – Są to elementy łączące ze sobą poszczególne moduły konstrukcji. Mogą być wykonane z różnego rodzaju materiałów. Możemy je podzielić ze względu na to czy są bierne czy też funkcjonalne. Elementy bierne to na przykład adaptery rurowe, łączące, adaptery do laminacji – łączą one tylko poszczególne moduły protezy, nie spełniają żadnej funkcji. Natomiast adaptery funkcjonalne stwarzają protezie nowe możliwości, są to adaptery obrotowe, przesuwne, amortyzatory.

Stopa protezowa - Bardzo ważnym elementem protezy modularnej jest stopa protezowa. To, w jaki sposób zachowa się podczas kontaktu z podłożem będzie miało wpływ na zachowanie całej protezy. Z mechanicznego punktu widzenia stopy możemy podzielić na dwie proste kategorie. Są to stopy z ruchomym stawem skokowym oraz sztywne stopy pozbawione przegubu. Możemy także dokonać podziału ze względu na tworzywo z którego zostały wykonane. Istnieje bardzo dużo takich rozwiązań, co jest ogromną zaletą systemu protez modularnych w których dzięki temu można dopasować każdy mechanizm indywidualnie do zapotrzebowania użytkownika. Ze względu na rodzaj tworzywa, z którego zostały wykonane możemy wyróżnić stopy ze stawem mechanicznym, pneumatycznym, hydraulicznym, pneumatyczno hydraulicznym, oraz najbardziej popularne stopy z włókna węglowego. Najnowsze osiągnięcia to stopy elektroniczne z wbudowanym mikroprocesorem.

TOMPLAST - proteza podudzia